Page 26

— Multifamily Properties Quarterly — July 2015

Design

C

olorado’s current real estate

market conditions, decreas-

ing vacancy rates and

increasing rental needs are

pushing the demand for

multifamily housing to quickly meet

the needs of the housing influx.

“Precast concrete structures offer

unsurpassed benefits for meeting

the growing multifamily market seg-

ment by fortifying the demand for

high-quality products with quick-

build schedules,” said Jason Lien,

executive vice president of EnCon

United.

Precast concrete is a high-perfor-

mance product and system used

to meet the needs of this growing

market segment. Precast concrete

consists of a specialized concrete

mix, which is cast into project-

specific, customized panels at

an off-site plant. The concrete is

placed into a mold or form, and

cured before being removed from

the form. The precast components

are then transported to the project

site for erection. The prefabrication

process allows all pieces to be cast

in a controlled environment and

erected on site, creating one of the

quickest and most efficient building

systems available. This allows own-

ers and builders to effectively meet

housing schedule demands, while

minimizing site and project delays,

and reduces overall costs. Precast

product advantages can include long

life span, continuous insulation, fire

resistance, vibration control, corro-

sion resistance, acoustical control,

speed of construction, greater qual-

ity control and finish consistency

with in-plant production. Plant pro-

duction also reduc-

es on-site labor and

lowers the job site

safety risk.

Multifamily pre-

cast components

generally require

elevated floors,

high-load capaci-

ties, open spans

and large bays in

the parking facili-

ties. Typical precast

components used

in the multifam-

ily market segment include podium

slabs, double tees, hollow core,

stair cores and wall panels. Precast

members also meet demands as

load-bearing elements, providing

high-load capacities and enabling

integration of structural, architec-

tural and insulated precast products

into one cohesive building system.

“Precast products are a viable mul-

tifamily solution because they serve

as structural components, provide

fire resistance and vibration control,

and can be integrated into architec-

tural precast components as well,”

said Lien.

Many residential complexes fea-

ture multiple stories of wood frame

or light-gauge steel construction

over an elevated concrete deck.

The podium projects allow for the

development of high-density proj-

ects, while reducing space and con-

struction costs. Podium slabs typi-

cally act as a structural foundation

floor and as a transfer slab for the

framed construction above, thereby

transferring loads directly into the

foundation walls. The podium slabs

typically are situated above parking

levels, creating partitions and com-

partmentalization, and require up

to four-hour fire ratings for safety

and compliance. A precast podium

design provides a cost-effective solu-

tion offering increased speed of con-

struction and limited environmental

impacts. Other podium advantages

include reduced job site congestion,

gravity and lateral load restraint, and

vibration and acoustic control.

Precast prestressed hollow-core

floor members are another option

for multifamily projects. Hollow core

is a prestressed concrete slab with

continuous hollow voids running the

full length of the product. The long

spans provide more open interior

space with less obstruction from

structural depth and columns. Ben-

efits of this precast solution include

vibration resistance, a two-hour fire

rating, easy floor penetrations and

Dave Bourgault

President,

Stresscon Corp.,

Colorado Springs

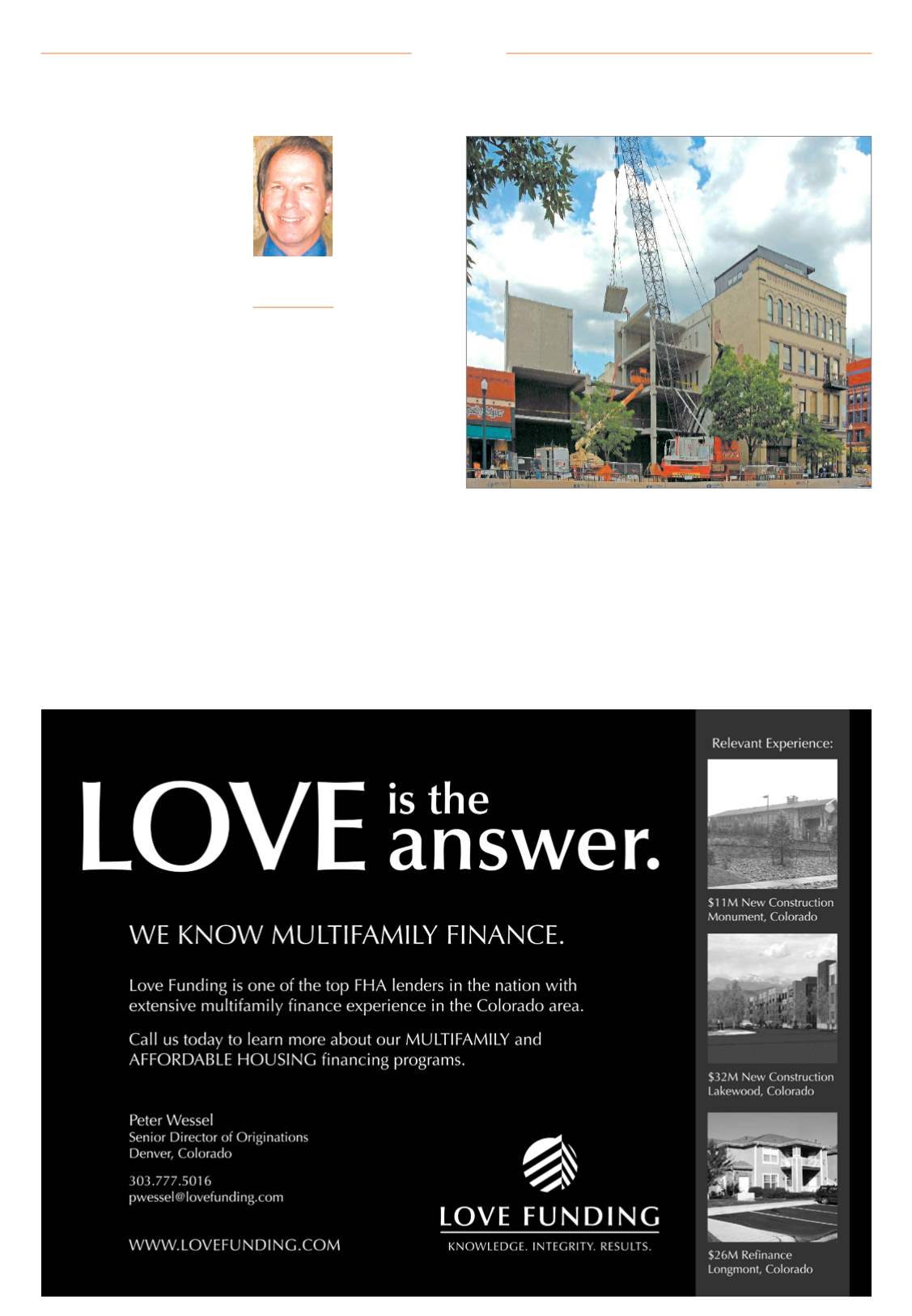

Precast architectural panels were used for Giddings Lofts in Colorado Springs.